NDT NONDESTRUCTIVE TESTING

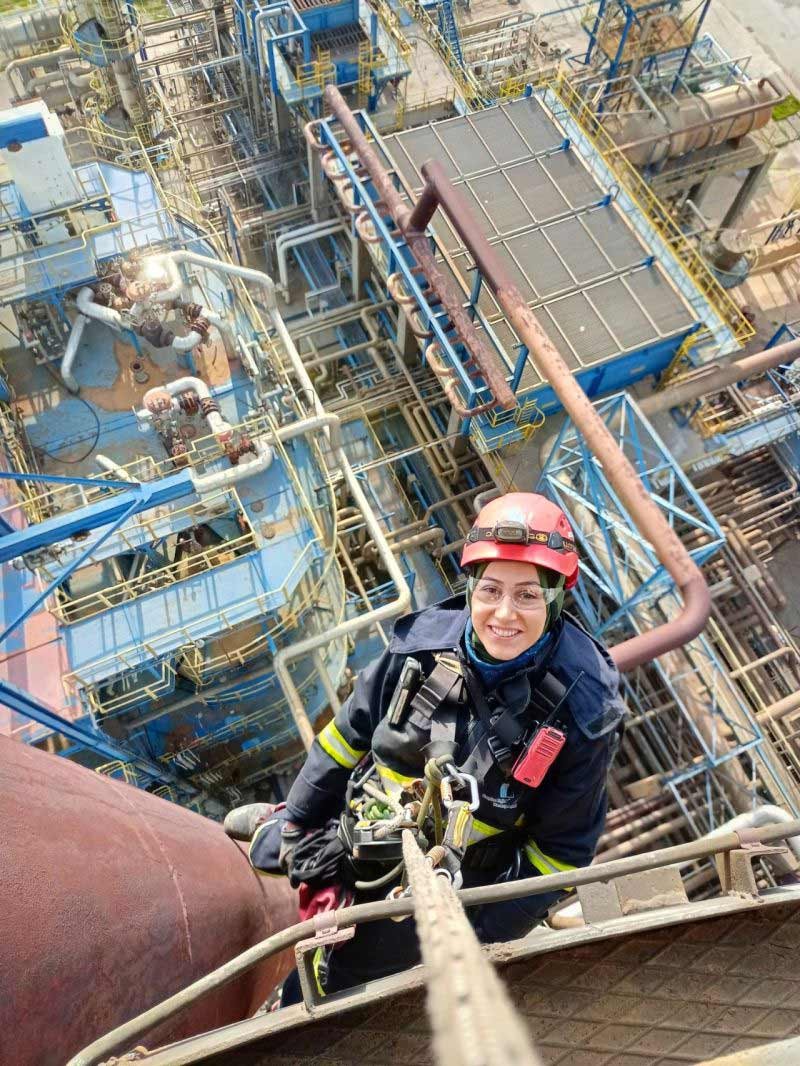

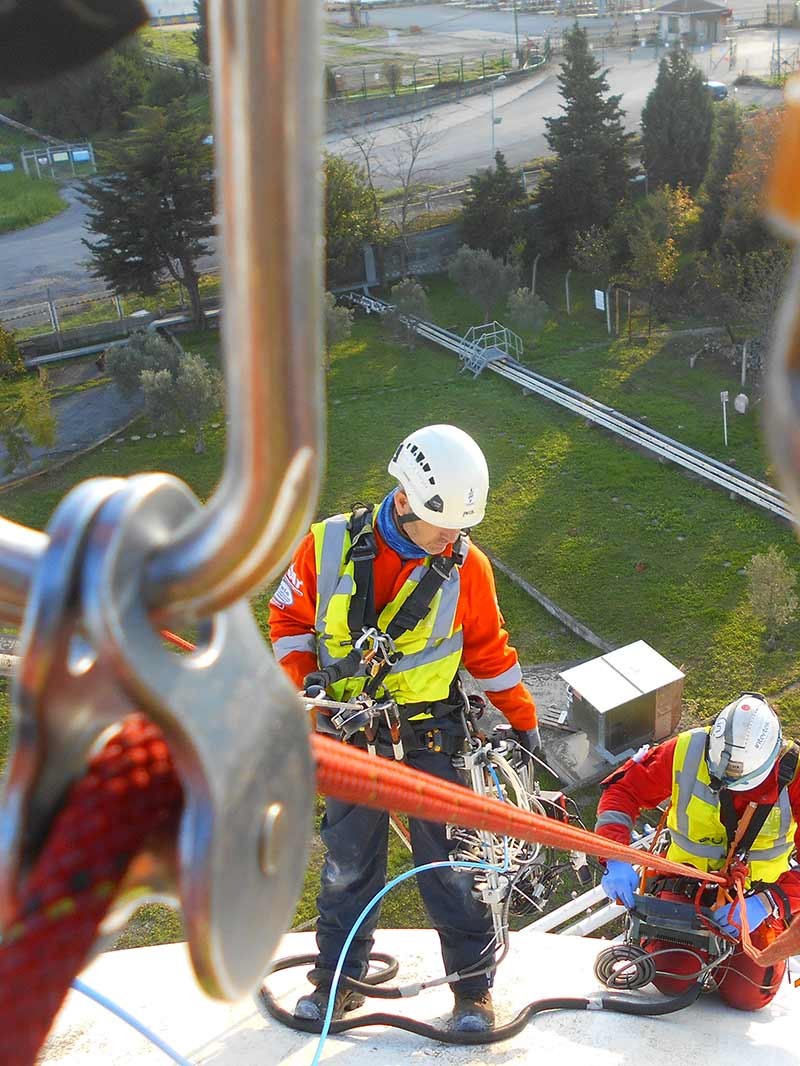

MIRA provides NDT non-destructive testing services, which are non-destructive testing and certification studies for the inspection of properties such as strength, integrity and impermeability of materials; parts or structures located in high or deep places where it is difficult to access by normal methods.

Non-destructive testing NDT work can be performed individually or periodically by the MIRA team.

Safe access of your company's own NDT specialists can be ensured to places where there is a risk of falling.

In cases where daily control is required, certified work at height training can be given to the employees of your company and periodic repetitions of these trainings can be made.

For more detailed information please contact us.

Our NDT Non-Destructive Testing Methods

MIRA provides NDT non-destructive testing services in production, construction and service processes in its branch, with its developed and specialized inspection and test techniques such as visual inspection, liquid penetrant test, magnetic particle test, ultrasonic inspection, radiographic inspection, Eddy Current electromagnetic induction test, inspection with phased array method and traditional non-destructive testing methods such as eddy current testing.

Industrial Facilities / Sectors We Serve

• Petro Kimya Tesisleri

• Oil Refineries

• Power Plants

• Wind Turbines

• Construction Industry

• Pipelines

• Iron and Steel Facilities

• Metal Fabrication and Steel Construction Industry

• Mining Industry

• Transportation and Infrastructure Sector

• Food industry

Gas / Oil Pipelines Weld Seam Inspections

&bull Automatic ultrasonic inspection (Rotoscan, TOFD)

• Manual ultrasonic inspection

• Radiographic examination (X-Ray Crawler)

• Liquid penetrant inspection

• Magnetic particle inspection

Corrosion Detection Inspections in Pipe Systems

• Inspection of closed-end pipe systems from the outside of the pipe(Pipe-Scanner ve Horse Shoe Pipe scanner)

• Exterior inspection of pipes that are difficult to reach (Guided Waves) (Lorus)

• Inspection of pipe systems that cannot be examined from the outside and can be opened at one end(Pipe Inspection Tools-PIT)

• Inspection of insulated pipes (without removing the insulation material)(Guided Waves ve Incotest)

Storage Tanks Inspection

Cylindrical Storage Tanks

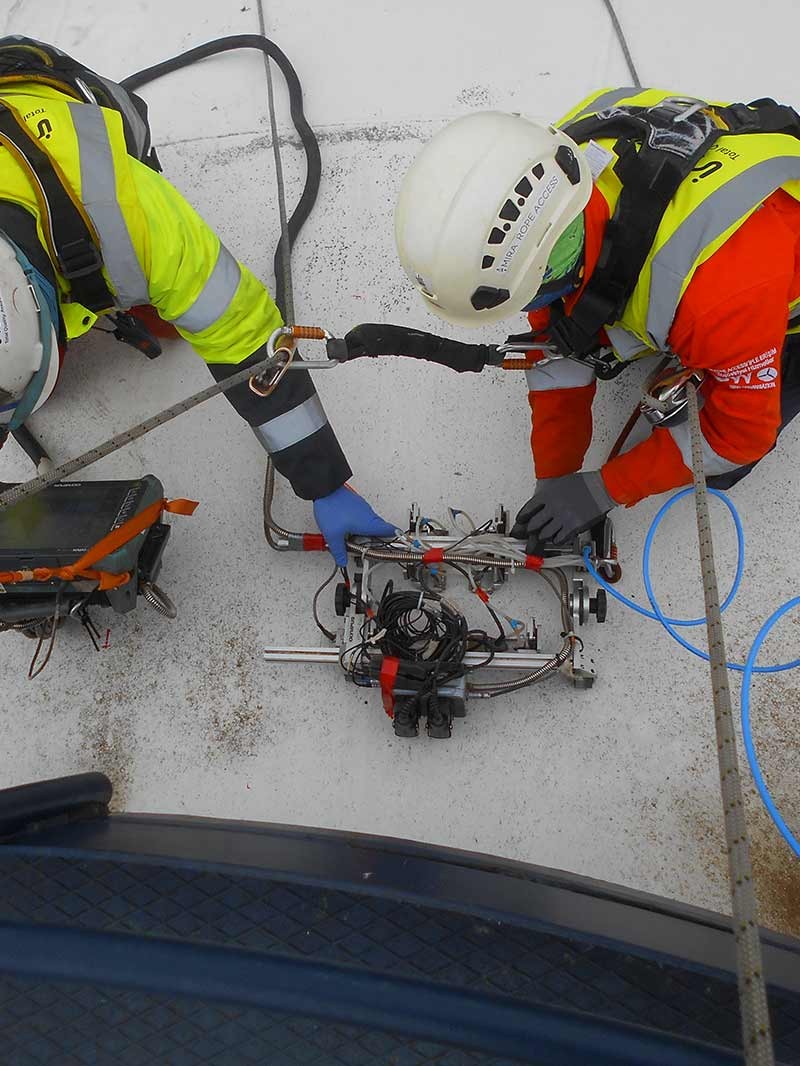

• Corrosion detection according to API 653 standard on side and roof sheets(Beetle-3 ve Beetle-4)

• 100% corrosion detection according to API 653 standard on Side Initial hardware sheets(Wallscanner)

• Corrosion detection on tank bottom sheets without emptying the tank (Lorus)

• 100% corrosion inspection on tank bottom sheets(Floorscanner ve Mini Floor scanner) (Slofec)

• Leakage control of weld seams of tank bottom sheets ( Vacuum Test)

• Inspection of weld seams of tank bottom sheets after repair (Manyetik Parçacık Muayenesi)

Global Storage Tanks

• Corrosion detection on spherical tank legs through surrounding concrete (Incotest)

• External corrosion inspection on spherical tank body sheets without emptying the tank(Mapscan)

• External inspection of spherical tank body weld seams without emptying the tank (TOFD)

• Internal and external inspection of spherical tank body weld seams after the tank has been emptied( Magnetic Particle Inspection )

Underground Storage Tanks

• After the preliminary inspection of the underground tanks, preventive and predictive maintenance inspections are applied with the appropriate ones of the above mentioned specialized industrial or traditional non-destructive inspection techniques, depending on the customer's request.

Port Pier Pile Pipes

• Corrosion detection inspection of the above the ground and underwater parts of the scaffold pile pipes(Incotest)

Pressure vessels

• Corrosion measurement in pressure vessels (Mapscan)

• Pressure vessel weld seams (Tofd)

Blast Furnaces

• Detection of cracks, corrosion errors caused by different thermal loadings and working environments in Blast Furnaces (Lorus)

• Detection of corrosion on furnace side walls over refractory material in melting furnaces(Incotest)

Heat Exchangers

• Detection of leaking faults in heat exchangers ( Helium leak test)

• Determination of corrosion and its amount in heat exchangers ( Eddy currents inspection)

Steam Turbines

• Detection of crack faults caused by the working conditions of turbine auxiliary machines such as rotors of steam turbines, turbine blades and compressors.

Food Industry Centrifugal Drums

• Periodic maintenance inspections of Centrifuge drums used in the Food Industry ( Industrial Radiographic Inspection) (Liquid penetrant inspection)